Before you begin shopping for your new electric vehicle, it’s good to have a basic understanding of the different types of electric motors used in EVs. In our companion blog, “How EV Motors Work”, we give you a brief overview of the science and engineering behind today’s electric motors…”spoiler alert,” magnets and electromagnetic fields are at the heart of what propels every EV motor.

Over the decades of global dominance by the internal combustion engine (ICE), there has been a multitude of different types of engines used in vehicles because, frankly, none of the engines developed during the 130+ years of the automobile has proven to be the best, most efficient design.

In the case of electric mobility, however, there are really just three main types of EV motors used in most automotive applications and that’s what we’re going to cover for you now.

Heads-up! We’re about to get a little technical but we’re tossing in a measure of history too, for a good foundation.

Asynchronous Induction Motor

First up, is the asynchronous induction motor, which was actually invented in 1885 by Galileo Ferraris, one of the pioneers of the AC (alternating current) power system. Ferraris, working independently, didn’t patent his work on the motor, so credit is shared with Nikola Tesla, who patented his “Electro Magnetic Motor” design, three years later.

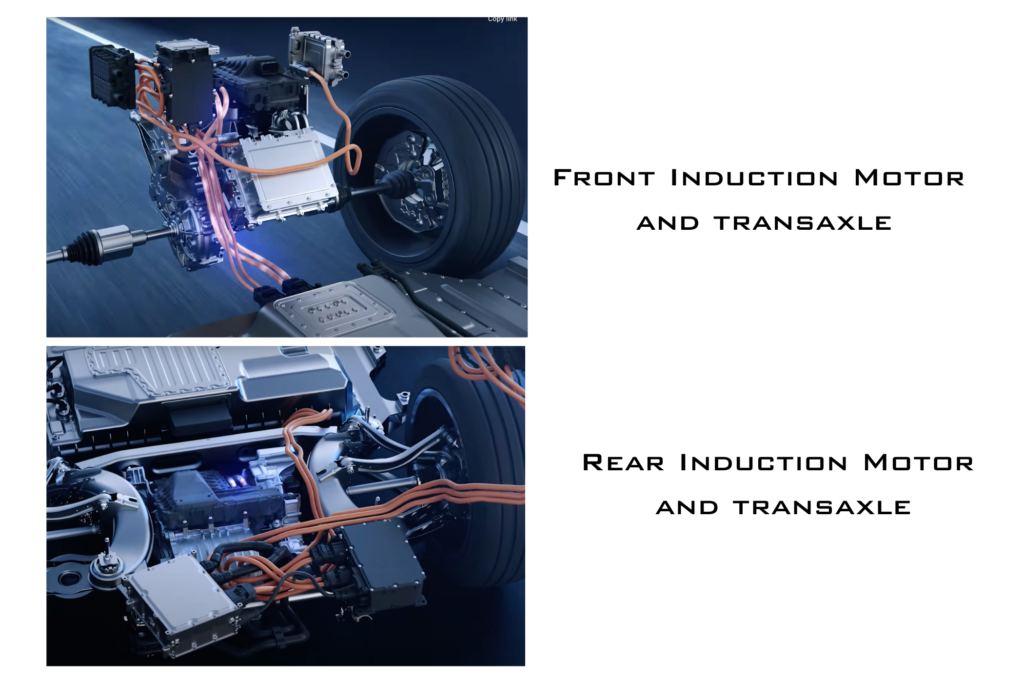

This type of EV motor is called asynchronous because the rotating magnetic field of the rotor and (static) stator are not synchronized. Electrical current and the rotating magnetic field produced by the stator are what move you when you mash the “go” pedal. On the flip side, when you need to slow down, the motor works like a generator, which allows the braking of the car to send energy back to the EV’s battery, known as (regenerative braking).

The (AIM) design is inexpensive to produce, it doesn’t require rare earth materials to create, it’s very reliable, and has good efficiency. It’s capable of on-demand performance too, which is why it is often used as the motor in all-wheel-drive cars like the Audi e-tron and Mercedes-Benz EQC. You’ll also find asynchronous motors in Volkswagen Group’s Modular Electric Matrix Platform (MEB) front-wheel-drive cars like the new ID.4.

Synchronous Permanent Magnet Motor

The big difference between the asynchronous induction motor and a synchronous permanent magnet motor is the way the rotating magnetic fields in the rotor and the (static) “stator” are produced and how they interact. In (SPM) motors, a rotating magnetic field is created by permanent magnets in the rotor. The rotating magnetic fields of the rotor and stator are locked (or synchronized).

The permanent magnets in the rotor help increase the power and efficiency of this type of EV motor. The ability to create a good amount of power from a small package is why permanent magnet motors are used exclusively in Plug-in-hybrid-electric vehicles (PHEVs). The Jeep Wrangler 4xe (Four-by-e) is a great example of a PHEV that uses a small, synchronous permanent magnet motor.

On the plus side, the (SPM) motor is tops when it comes to efficiency, and for cars using just one electric motor, the synchronous permanent magnet design is what’s used. On the downside, this type of EV motor uses permanent magnets that are made from rare earth materials found mainly in China where they are mined from the earth. For this reason, most manufacturers try to reduce the usage of these rare earth materials in their EV motors.

Permanent magnet motors can be found in the Kia EV6 and VW Group (MEB) cars for use on the rear axles. You’ll also find the (SPM) in the Jaguar I-PACE, Audi e-tron GT, and Porsche Taycan.

Electrically Excited Synchronous Motor

The final of our three main types of EV propulsion brings us to the electrically excited synchronous motor (ESM). Even though permanent magnet synchronous motors are the most efficient of the three, the rare earth materials needed to construct them can be an issue. So, manufacturers like BMW, use a hybrid design that features synchronous motors that do not require the mining of rare earth materials.

Instead of using permanent magnets in the rotor to create current, the (ESM) uses brushes and what’s called, slip rings. The (ESM) is less expensive to manufacture than a permanent magnet synchronous motor and has an efficiency rating of up to 93% according to BMW, which is close to the efficiency of a (SPM) motor.

However, because this type of EV motor uses brushes to help generate electric current, it will require the replacement of these components at some point in the life of the motor. The BMW iX, and i4 use electrically excited synchronous motors in the United States while the same motor is also found in the BMW iX3 that’s built and sold only in China.

By Mark Arsen, LeithCars.com

Leave a Reply